Enviro-Flow utilizes the Flow-240 Inversion System pair with Flow-Liner HVAC CIP-Duct for a car wash vent duct.

Cured-In-Place Pipe (CIPP) Inversion

Enviro-flow's most common pipe lining process is the inversion method. This method inverts a resin impregnated liner through the existing pipe, then holds the liner under pressure to keep it expanded against the host pipe so it can cure. After curing, the resin hardens to the strength of a newly installed pipe. There are many applications where CIPP can be utilized, if you're not sure if CIPP will work for your project, don't hesitate to give us a call. Save your money and your time.

CIPP is rapidly growing in popularity due to its many benefits:

- Little or no excavation, little clean up work/time

- Cost Effective, can save the customer 50%+

- Fast and Efficient Installation

- Helps eliminate future water infiltration/root intrusion

- Environmentally Friendly

Reinstatement Cutters

A Reinstatement Cutter is a robotic lining reinstatement cutter specially designed for opening branches of lined pipes; meaning if your lining project has a tee or a fitting, Enviro-Flow® can line through the pipe, and then cut an opening for the branch line. This results in a smooth professional branch line reinstatement finish. Cutters can also be used to remove unwanted obstacles in the pipe (i.e. concrete, hard scale, foreign objects protruding into the pipe). Enviro-flow® offers branch line reinstatements from 3” to 24”.

Neofit®+Plus Expandable Pressure Pipe

The NSF-61 approved Neofit®+Plus Expandable Pressure Pipe (EPP®) System is a non-invasive option for leaking water service pipes with inside diameters from ½” to 2”. The Neofit EPP® forms a continuous barrier between existing pipe and drinking water – ideal for Lead Replacement Programs. The EPP can be installed in steel, copper, plastic, and lead pipes, and in lengths up to 300 ft. The smooth bore and thin-wall liner provides the same or increased flow capacity. Neofit®+Plus often only requires a single small access pit, saving yards, sidewalks, floors, and more, from demolition. The speedy efficient Neofit®+Plus process allows for many installations a day and immediate return to service.

QUICK-LOCK POINT REPAIR

NSF 61 approved for standalone point repair, or for pre-lining under high infiltration, Quick-Lock sleeves restore a pipe’s structural integrity and seal out groundwater. They minimize diameter loss and outlast any other rehab. Certified to ASTM Standard F3110-14. Point repair sleeves available 4"-32"

QUICK-LOCK END CAPS

NSF 61 approvedQuick-Lock end caps strengthen a CIPP liner at its most vulnerable points—the ends. Stronger and easier to install than other end caps, they’re a must-have insurance policy for installed CIPP. Certified to ASTM Standard F3110-14. End caps available 8" - 32"

Infiltration - Longitudinal & Circumferential cracks - Root intrusion - Holes - Separated joints - Offset joints - Abandoned laterals

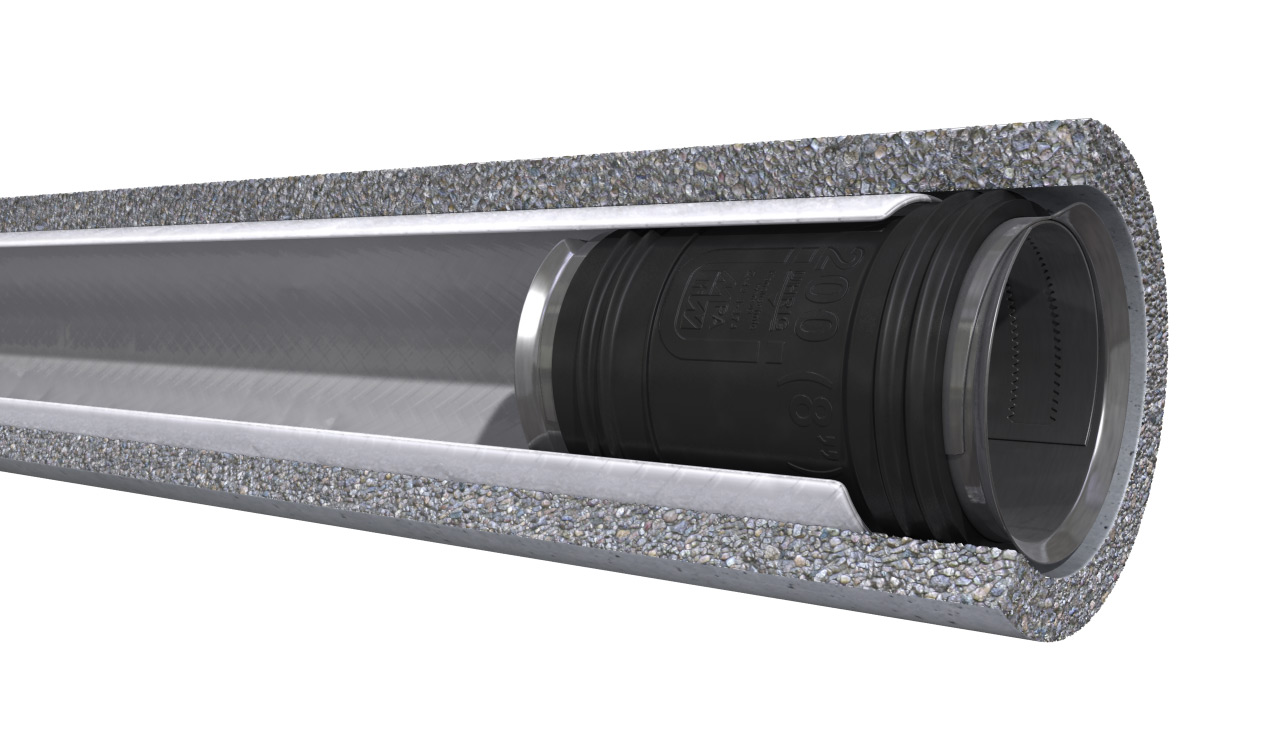

Flow-Liner Winch-in-Place-Pipe (WIPP) Lining

WIPP® is a flexible sliplining solution for the trenchless rehabilitation of pressure pipes. The system consists of a flexible Kevlar® reinforced liner and specially developed end fittings. Our WIPP liner is not bonded to the host pipe and is self-supporting. An annulus remains between liner and the host pipe. Developed by experienced engineers, the system is suitable for different media as well as various application needs and has already proven itself in numerous projects. Our WIPP system handles 6"-20" pipe diameters. See below for more information on WATER, OIL and GAS applications.

Televising and Inspection

How do you find problems in your sewer system without costly guesswork and excavation? Our specially designed color cameras pinpoint problems in pipes as small as 2” in diameter to as large as 96” in diameter. Trouble spots, such as cracked or broken tiles, offset joints, and blockages are quickly and precisely located without excavation. Service includes audio-video tape and computer-generated report of the inspection. Enviro-Flow’s television inspection service can also help you meet the EPA guidelines for your newly installed sewer lines.